Discover the Conveniences of Using a stretch wrapping machine for Effective Packaging Solutions

Automation has brought forth significant advancements, such as the stretch wrapping machine. What makes these makers a game-changer in the product packaging industry?

Comprehending the Performance of Stretch Covering Machines

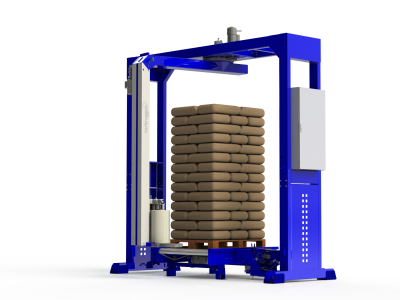

Pioneering the packaging market, stretch covering equipments improve the procedure of firmly product packaging items for transport or storage. These innovative equipments employ an easy yet reliable device, utilizing a stretchable plastic film that is twisted around things, providing stability and security. The items, typically prepared on a pallet, are rotated as the film is dispensed, guaranteeing a limited and safe and secure wrap.

The movie's flexibility offers a double function: it snugly binds the items together, decreasing the danger of damages because of activity, and it provides a barrier against dust, moisture, and other potential damaging aspects. Additionally, the clear nature of the stretch film permits easy identification of the packaged items.

The equipments vary in their operation mode, with some being semi-automatic, requiring marginal human treatment, and others being completely automatic, efficient in individually handling the entire covering procedure. No matter their mode, stretch covering makers are a foundation of efficient and secure packaging.

Just How Stretch Wrapping Machines Enhance Efficiency

Increasing performance degrees considerably, stretch wrapping makers enhance the packaging procedure with their automated abilities. These advanced equipments allow companies to cover a high volume of packages swiftly and effectively, delivering a regular wrapping output that hands-on methods merely can not match. This speed and uniformity equate straight right into enhanced performance, allowing businesses to satisfy requiring supply routines and consumer expectations.

Additionally, stretch wrapping devices call for minimal human treatment. Once the maker is established and the wrapping criteria are set up, the device can run independently, maximizing staff members to concentrate on other critical tasks. This automation not just reduces labor expenses yet also gets rid of human mistakes, guaranteeing the top quality of covering remains constant.

Additionally, using stretch wrapping equipments often causes much less downtime. stretch wrapping machine. With their robust design and trustworthy procedure, these machines are less susceptible to malfunctions and upkeep issues, guaranteeing undisturbed process and boosted performance

Reducing Material Waste With Stretch Wrapping Machines

While improving performance, stretch covering machines also play a critical role in reducing material waste. The precision of these devices guarantees that each bundle is wrapped with the specific quantity of product required, decreasing excess waste. This accuracy not just results in an aesthetically pleasing and constant bundle, yet additionally contributes considerably to environmental sustainability.

Basically, the utilization of stretch covering devices in a product packaging line is not only an action towards reliable efficiency, yet likewise a jump towards green methods by significantly lowering material waste.

Expense Decrease: A Secret Benefit of Stretch Covering Machines

In enhancement to mitigating material waste, another considerable benefit of stretch covering machines is their potential for expense decrease. These equipments are reliable, requiring less hands-on labor for product packaging items, therefore reducing labor costs.

Additionally, stretch wrapping makers make use of much less product to package items firmly as contrasted to traditional wrapping methods. This efficient use of materials not only decreases waste however also reduces expenditure on packaging materials.

The devices likewise reduce damage to products during transport. With sturdy and secure packaging, the risk of product damages declines, lowering the prices related to item returns and substitutes.

Lastly, the speed and effectiveness of stretch wrapping devices can boost production rates. Faster product packaging times suggest that services can package and ship more items in much less time, improving overall performance.

Applying Stretch Covering Machines in Your Packaging Refine

Offered the excellent benefits of stretch covering makers, integrating them into your product packaging process can be a game-changing decision. The execution process requires mindful planning and training to ensure optimum use. An evaluation of the current product packaging process is essential to figure out the optimal machine type and size (stretch wrapping machine). The choice should straighten with the bundle measurements, weight, and the volume of things to be wrapped daily.

Training personnel on maker procedure is essential. This consists of comprehending the maker's performances, fixing common issues, and sticking to safety and security standards. By doing so, services can make sure an effective, affordable packaging procedure, enjoying the full advantages of read review their financial investment in stretch wrapping machines.

Verdict

Finally, stretch covering devices offer reliable, economical packaging remedies. They improve productivity and decrease waste by exactly wrapping things with stretchable plastic movie, meeting high-volume needs effortlessly. These machines make certain product stability and defense, while also supplying aesthetically pleasing plans. For companies intending her response to enhance their packaging procedures, this technology supplies an effective course in the direction of enhanced performance and cost financial savings.

Once the device is established up and the covering criteria are set up, the machine can operate separately, freeing up workers to concentrate on various other essential tasks.While enhancing productivity, stretch wrapping devices additional hints likewise play a critical duty in reducing material waste.Given the impressive benefits of stretch wrapping machines, incorporating them into your product packaging procedure can be a game-changing choice - stretch wrapping machine. By doing so, businesses can ensure an efficient, cost-effective packaging procedure, gaining the complete advantages of their investment in stretch wrapping devices

In final thought, stretch wrapping devices offer efficient, cost-efficient product packaging remedies.

Comments on “How to service a stretch wrapping machine for ongoing use”